| Warehouse and Transport Logistics | ||

|

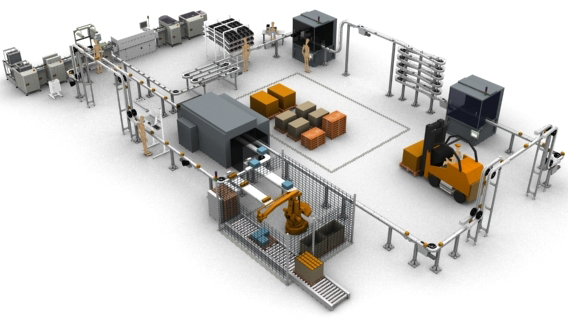

A Warehouse Management System, or WMS, is a key part of the supply chain and primarily aims to control the movement and storage of materials within a warehouse and process the associated transactions, including shipping, receiving, put away and picking. The systems also direct and optimize stock put away based on real-time information about the status of bin utilization. |

|

The objective of a warehouse management system is to provide a set of computerized procedures to handle the receipt of stock and returns into a warehouse facility, model and manage the logical representation of the physical storage facilities (e.g. racking etc), manage the stock within the facility and enable a seamless link to order processing and logistics management in order to pick, pack and ship product out of the facility. Warehouse management systems can be stand alone systems or modules of an ERP system or supply chain execution suite.The primary purpose of a WMS is to control the movement and storage of materials within a warehouse - you might even describe it as the legs at the end-of-the line which automates the store, traffic and shipping management. In its simplest form, the WMS can data track products during the production process and act as an interpreter and message buffer between existing ERP and WMS systems. |

||

©All rights reserved by 2010-2011 Air Ways Logistics Pvt. Ltd. Powered by People Craft Consulting Services